There are a wide range of suspended ceilings available to choose from these days and there’s sure to be one to suit your requirements. Whether its for your home or office, this guide is to help you narrow down your choice of options.

Exposed Suspended Ceilings

These are the most common type of drop ceilings available. There are a huge range of tiles available with different face patterns, acoustic properties and fire ratings. The grid system itself can be a 15mm or 24mm wide tee system and the most widely used sizes are 600x600mm or 1200x600mm. There are also a choice of edge details, square edge sometimes called butt edge or tegular edge.

One of the advantages of this type of design is that it facilitates a very quick and fast installation. Another advantage is that it permits easy access, so maintenance can be carried out in the void and the tiles themselves can also be easily be replaced should there be any damage.

Concealed Suspended Ceilings

These used to be very popular but due to access problems they seem to be out of favor these days. The original concealed edge detail made it almost impossible to replace the odd water damaged/broken tiles.

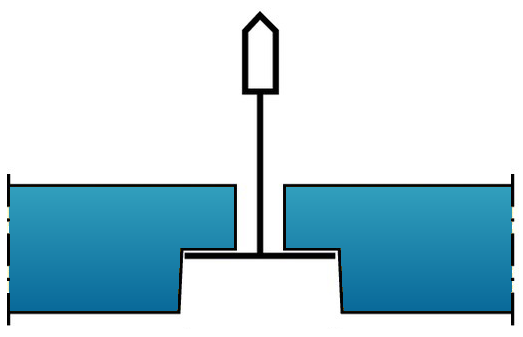

There are some types of concealed ceilings that do allow easy access by using an edge detail like this one shown below:-

Ecophon are one of the manufacturers who make this type of ceiling.

Plank Ceilings

There are a few different types of plank ceiling, some are specifically designed for spanning across corridors to allow easy access to services whilst others like Luxalon are superb for fantastic looking wide open spaces or reception areas. Plasterboard ceilings are very good when it comes to blocking sound and usually have very high fire ratings. The disadvantage of MF ceilings is the cost which is more than the others because they have to be skimmed/taped and filled and also decorated after fitting. This also has the downside of an increased fitting time.